UK automotive manufacturers are rolling out plans to increase production of lithium-ion batteries, but a large-scale capacity increase will be needed to meet ambitious targets for electric vehicle (EV) adoption.

Hyperbat, a joint venture between Williams Advanced Engineering and Unipart Manufacturing, said this week it will open a new plant in Coventry in the first quarter of 2019 to produce batteries for hybrid and electric vehicles. The initial plan is to develop capacity for 100,000 vehicles, but this could expand as customer demand increases, Frank Nigriello, Unipart's director of corporate affairs, said. The battery chemistries and cell formats will be tailored to individual car manufacturers' requirements.

The first customer for Hyperbat batteries is Aston Martin, with a limited production run next year of 155 samples of its Rapide E luxury electric model for delivery in the fourth quarter. Aston Martin this week detailed some of the specifications of the car, which will have a 65kWh lithium-ion battery capacity. Following that test run, Aston Martin will start production of its Lagonda EV range from 2021.

Japan-based carmaker Nissan's Sunderland plant is the only other EV battery maker operational in the UK, producing 2 GWh/yr of lithium-ion batteries for 60,000 Nissan cars a year. Nissan agreed last month to sell the plant to Chinese renewable energy company Envision after a deal to sell it to Chinese investment firm GSR Capital fell through in July. Nissan will hold a 25pc stake in a new company formed by Envision.

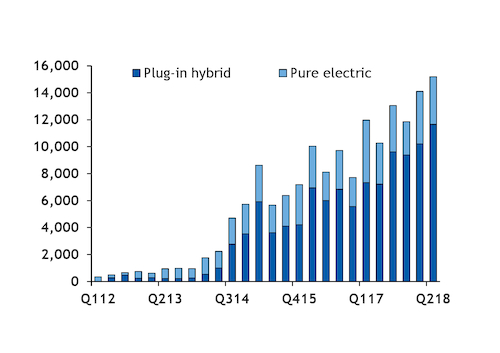

Registrations of hybrid and electric vehicles totalled 91,069 in January–August, up by 27.4pc year on year, according to the SMMT. Registrations in August were 88.7pc higher than in August 2017. Most carmakers that do not already have EVs on the market plan to introduce models in the next two years, which will further increase sales and demand for batteries.

The UK produced 2.7mn vehicle engines last year, SMMT data show, well above the combined capacity of 160,000 units/yr of the battery plants. The government has set a target of 2040 to end the sale of conventional petrol and diesel cars and vans, requiring a ramp up of UK battery production capacity and imports of batteries from Europe and Asia-Pacific.

The UK Battery Industrialisation Centre (UKBIC) is building an £80mn ($105mn) plant scheduled to start production in 2020 to develop and prove materials, cell design, and manufacturing processes that can be implemented in large-scale battery plants. And battery materials producer Johnson Matthey is building a demonstration-scale plant in Lancashire with a capacity of 1,000 t/yr capacity scheduled to start production in 2021-22.

The rise in demand for batteries has prompted Japan-based Mitsubishi Chemical to re-open its electrolyte plant in Stockton-on-Tees. It had been established to supply the Nissan plant and other battery producers in Europe, but was mothballed in 2016 because of insufficient demand.

Technology developments

Aston Martin and Williams are working on battery cooling technology to address concerns about vehicle speed and range, as overheating can reduce the amount of power that a battery generates.

Battery efficiency is a focus for the UK Research and Innovation funding agency, which yesterday announced a new £25mn funding competition to offer grants to businesses with projects to develop batteries for future electric vehicles. It stipulated that the projects should aim to make it easier to scale up battery production and use, build the UK supply chain and address technical challenges, including the temperature ranges within which a pack can efficiently operate, increasing the energy density per cell, and increasing the power density per pack.

Appliance manufacturer Dyson is investing £200mn in its Hullavington electric vehicle development and testing site, although it could opt to produce the vehicle outside the UK.

EV charging station developer The EV Network (EVN) yesterday outlined its plans to roll out fast-charging stations across the UK in partnership with Swiss battery and energy storage systems producer Leclanche. "The existing EV charging infrastructure is not ready for the mass uptake of EVs that we are going to witness over the next 10 to 20 years," EVN co-founder Reza Shaybani said.