The inclusion of marine fuel emissions in the EU's Emissions Trading Scheme (ETS) set to begin in 2024 could drive up biofuel for bunker sales in Rotterdam, but uncertainly lingers around Netherlands biofuels marine fuel subsidies.

The inclusion of maritime shipping in the EU's ETS will require ship owners traveling within the EU's territorial waters to pay for 40pc of their greenhouse emissions from 2024, rising to 70pc from 2025 and to 100pc from 2026.

Biodiesel, as a plug and play fuel, has gained traction with ship owners. Rotterdam biofuel bunker blends sales more than doubled to 791,653t in 2022 from 301,051t in 2021.

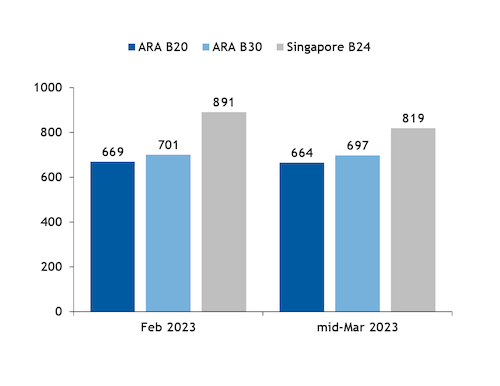

Rotterdam B20 biodiesel was priced at a $98/t average premium, or a 17pc premium to very low-sulphur fuel oil (VLSFO), in the first half of March, Argus data showed. Rotterdam B30 biodiesel was pegged at $131/t average premium or a 23pc premium to VLSFO during the same period.

The Netherlands government subsidizes sales of biofuels for bunkering. Without the Netherlands subsidies, B20 and B30 would have been priced at 41pc, or a $232/t premium, and 59pc, or a $331/t premium, to VLSFO, respectively, in the first half of March. But the Netherlands marine use subsidies are not set in stone. They are reviewed annually and could decrease or even be scrapped.

The Netherlands government excluded the maritime sector from its domestic biofuels ticket scheme in 2021 on the back of the disproportionate use of biofuels in shipping in 2020.

Fuel suppliers in the Netherlands' shipping sector can since then only claim renewable fuel units (HBEs) from biofuels that are produced from feedstock listed in Annex IX part A of the EU's revised Renewable Energy Directive (RED II), and therefore classify as advanced. The decision came after fuel suppliers obligated under the Dutch biofuels blending mandate had made increasing use of the option to claim HBEs generated by using renewable energy in seagoing shipping in 2020. Biofuels used in maritime shipping covered almost 30pc of the overall blending target in 2020.

Still, in the 2022 compliance year around 32pc of total HBEs issued — or around 23.6mn HBE-Gs — came from the maritime sector. This prompted the Dutch government to remove brown grease, a popular feedstock used for biofuels in shipping, from the list of approved advanced feedstocks in the HBE scheme on 1 January 2023. Tickets for 2022 compliance can be surrendered in the first quarter of 2023.

By contrast, Singapore, the biggest bunkering port in the world, does not offer biofuel for bunkering subsidies. Singapore biofuel marine fuel sales were at 140,000t in 2022 and data for 2021 is not available. Singapore B24, the most common biofuel bunker blend there, was assessed at $819/t average in the first half of March, 19pc and 15pc higher than Rotterdam B20 and B30, respectively (see chart).