US Gulf coast refineries are maintaining typical utilization rates so far this summer, despite the challenges extreme heat can bring to industrial operations.

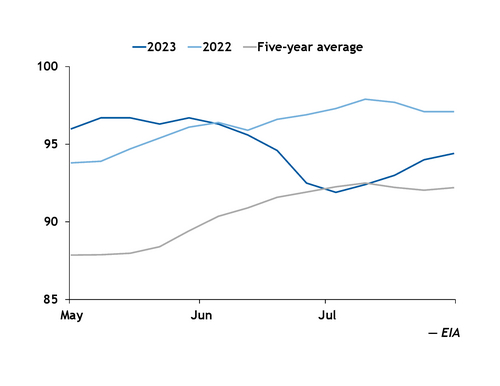

US Gulf coast refinery utilization rates have largely remained above the five-year average so far this summer, despite prolonged periods of extreme heat that can cut unit efficiency, stress equipment and increase the chance of power outages (See table). Gulf coast utilization climbed to 94.6pc in the week ending 11 August, which is typical for the summer season, while crude throughputs were 8.96mn b/d, according to the Energy Information Administration (EIA), down from 9.09mn b/d the same time a year earlier. Gulf coast refineries produced 2.18mn b/d of gasoline the same week, down slightly from 2.23mn b/d a year prior.

The Houston, Texas, area is currently in a three-week stretch of daily highs above 100°F, with below-average precipitation, according to the National Weather Service (NWS). Temperatures throughout Texas and the Gulf coast are expected to remain "likely above" average in the next two weeks.

The summer has not been without its challenges for operators. Utilization rates took a temporary dip in July from 95pc to 91pc, and there have been several sizeable outages in the region in July and August. This includes multiple flaring events and maintenance to ExxonMobil's 369,000 b/d refinery in Beaumont, Texas, as its coker unit ran at reduced capacity because of heat-related issues, according to sources familiar with operations. Marathon Petroleum's 593,000 b/d Galveston Bay refinery in Texas City, Texas, also reported an unplanned fluid catalytic cracking (FCC) unit shutdown on 21 July and a sulphur recovery unit malfunction the next day after after a tail gas treating unit overheated.

But overall regional production has remained robust heading into the late summer and the height of the Atlantic basin hurricane season — which can prove to be a significant threat of a different source to refiners.

Heat saps efficiency

While refinery operations involve high temperatures, extreme heat can curtail efficiency on different units and processes and lower a refinery's output by as much as 4-5pc, according to Andrew Lipow, an industry analyst and president of Lipow Oil Associates.

Most US refineries use water to regulate unit temperature and are designed to cope with variations in heat. But even those systems could be reaching their limits, according to Khush Nariman, a downstream industry consultant and partner at McKinsey. Air-cooled units, although less common, are similarly susceptible to temperature rises.

Hotter, less dense air also renders fluid catalytic cracking (FCC) unit regenerators less effective at cleaning the catalyst used to break large hydrocarbon molecules, lowering unit efficiency.

Maintenance work can also be challenged by hot weather. As ambient temperatures approach the flash points of chemicals used to clean tanks and equipment at refineries and petrochemical plants, scheduled maintenance may be delayed until conditions are safer.

Maintenance that is not delayed may also take longer as crews are more likely to use less volatile, less efficient chemicals and degreasers. In some cases only water can be used, which can significantly extend cleaning times.

Hurricanes season threats loom

This year's record Gulf coast heat has so far coincided with relatively mild tropical storm activity, but forecasters have upped expectations for an intense peak to the hurricane season through October. This would increase risks for refinery outages.

The National Oceanographic and Atmospheric Administration (NOAA) upgraded its forecast earlier this month to a 60pc likelihood of an "above-average" hurricane season because of "record-warm Atlantic sea surface temperatures." NOAA now projects 14-21 named storms, of which, 6-11 will become hurricanes, and 2-5 of those will reach major hurricane status — category 3, 4 or 5 storms — with sustained winds of 111 mph or higher.

Major storms can shut-in offshore Gulf of Mexico crude production, which is a key source of crude for Gulf coast refiners. A "high-impact" hurricane that disrupts Gulf of Mexico crude production by 80pc could increase monthly average retail gasoline prices by up to 30¢/USG, according to a recent EIA report. But hurricanes have had less impact on energy markets in recent years as a greater share of US oil and natural gas output comes from onshore.

The high winds and flooding tied to hurricanes still pose a threat to Gulf refineries and petrochemical plants, however, particularly for power loss. A US Chemical Safety Board analysis of chemical releases during hurricanes urged the US Federal Energy Regulatory Commission to adopt more stringent standards for the electric grid to reduce accidents caused by hurricanes and unpredictable extreme weather.

Regional power grids can also be stressed without storms, leading to a loss of power at the many refineries that do not have onsite generation. The Electric Reliability Council of Texas (ERCOT), which operates the power grid for most of the state, set 10 new all-time peak demand records this summer. While operations have been stable so far, ERCOT issued an voluntary conservation notice on Thursday, warning that the margin between demand and available generation could get dangerously narrow from 3pm-8pm.